Power handling

Product/Power Handling

Lifting Column for Drums:

The fixed Lifting Columns series is projected and manufactured to support some kind of machine such as: Vacuum Conveyors, Drums, Pharma BIN. They are mainly used in the chemical, pharmaceutical and food industries to optimize the production processes of handling of powder (handling, dosing, mixing) and avoid the ‘cross-pollution’.

Lifting Device

Lifting Coulmn for Drums 1a

Lifting Coulmn for Drums 1b

Screw Sampler

Powder Transfer System

Drum Emptying Station

Mobile Lifting Device To Fit And Remove Emptying Valves Of Chemical Reactors

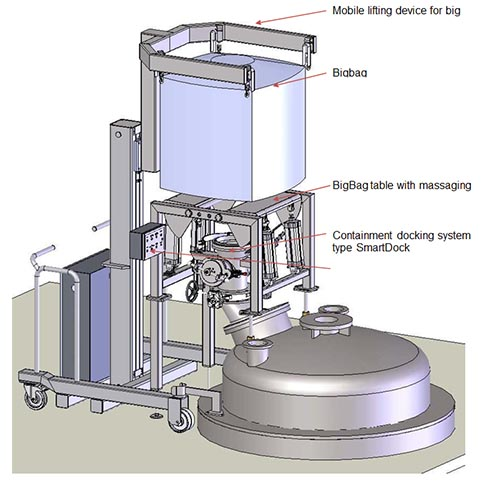

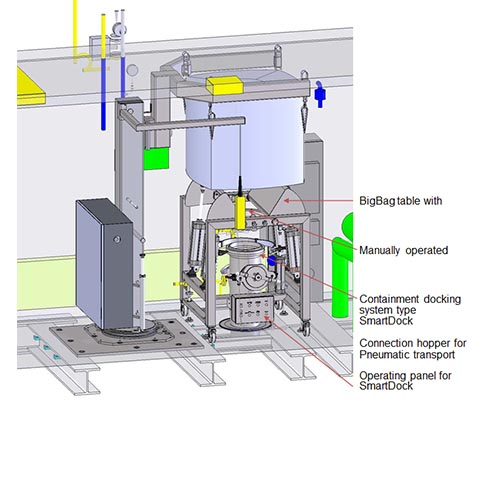

Contained Powder Feeding Of Chemical Reactors With BigBag Docking system

BigBag Emptying Station with Containment Docking System Type

Pneumatic Vibrators

The Pneumatic Vibrators have been projected and manufactured to be installed on hoppers, silos, bin, mixing and dosing machine and in all cases where there are problems of powder block during the discharge phase

Lump Breaker

The Lump Breaker allows to crush the lumps that could form in the materials during the production process or the handling of powders.These systems are particularly suitable for hygroscopic materials or those that tend to clog, and thanks to their versatility can be used in all industrial sectors.

Conveyor Running Hoppervac

The Vacuum Conveyor type Hopper Vac is used when it’s necessary to charge a tank/container used also as a storage unit to charge another machine. In this case the HOPPERVAC is used not only as a powder transfer system but also as a container of powder accumulation.

Conveyor in Vacuum

The Vacuum Transfer Systems are manufactured and used in the pharmaceutical, chemical and food Industries for the transfer of powder and grains. It can be used in both production (for the load of: mixers, mills, dryers, batching machine, bin, etc.) and packaging division (for the load of: Filling Machine, Tabletting Machine, etc.).

Bin Blender - Tumbler

The Tumbler is designed for mixing and homogenization of dry powders, and is primarily used in the Pharmaceutical and Chemical Industries in all those processes of handling of powders in which there is the need to mix homogeneously the powders directly inside Bin without the loading, unloading and cleaning operations of the mixer.

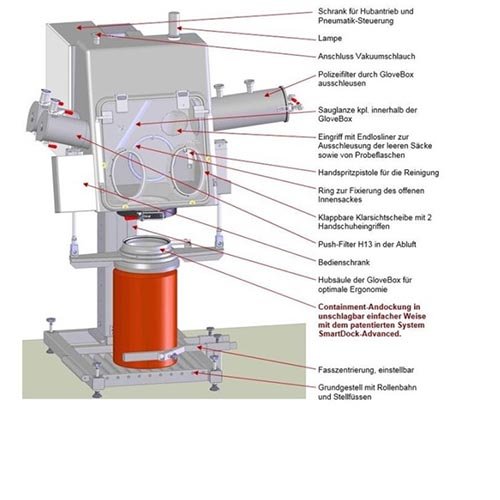

Containment Drum Emptying Station For Powder Type R-DCS-B

Better Ergonomic Complete cleaning in contained matter, because no hose around suction lance! Simple replacement of the air filter (Push-filter) Simple replacement of an additional police air filter (Push-filter) Most favorite and simple docking procedure of the drum liner Closed loop of the product hose for cleaning up to 3 bar!

Solids Calibrating

Solid calibrating for the chemical and pharmaceutical industries. No off-the-shelf item but custom-tailored to your individual needs

Solid Comminution

Our engineering department will be pleased to assist you in integrating units into your overall plant planning. And For emergencies or routine maintenance, our service organization is on call with original spare parts.

BIN Pharma

The BIN are completely made in stainless steel AISI 316L and are used for the containment and the powder transfer system in the production and manufacturing areas. Their design and versatility make them particularly suitable to charge, both for gravity and Vacuum Conveyor, Tabletting machine, filling machine etc.

Big-Bag Empty Structure

The Big-Bag emptying structure is a modular system with different configurations, depending on the type of application, used for empty Big-Bag.The easy introduction of the Big-Bag on the frame as well as the emptying without powder emission (powder proof) make the structure SBB extremely easy in its use.

Bag Emptying System

The manual bag emptying system represents the ideal solution for emptying of powder or granules in the spaces with the complete absence of dust. It consists of a grid with a support front shelf mounted on a hopper supported by four feet and a hopperwith door protection .

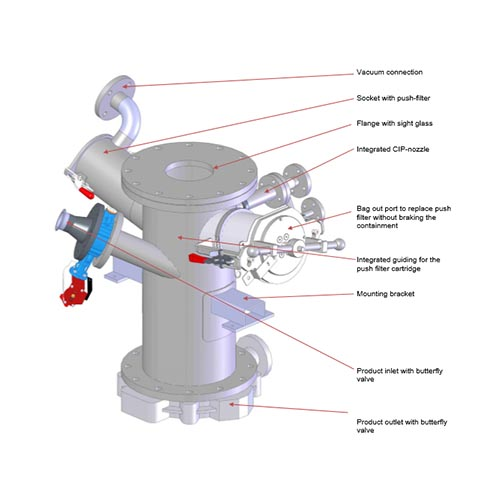

Contained Drum Unloading Type Compact

A compact insulator station for draining product from barrel down to reactor with its patented SmartDock system. This provides a very tight and safe procedure that can meet more stringent requirements for handling hazardous materials (OEB 5). The station is handled independently by only one operator and is designed to be easy to work with.

Drum Containment

The DCS Liquid was specifically developed for toxic and corrosive liquids, achieving containment levels of <1 ppb.The safe, contained emptying and filling of drums using the suction lance housed in a special venting tube with a sealing plug is thus made possible without additional precautions, such as full protective clothing or large Laminar Airflow booths.

Containment Sampler

Sampling in the containment area presents users with major challenges. On the one hand the system always must remain closed due to the toxic media it contains, on the other hand, it has to be opened for sampling.With its automated in-line sampling system, offers maximum safety and ease, in order to increase efficiency in process management.

Vaccum Powder Transfer

The PTS Powder Transfer System is an exceptionally effective and reliable method of transferring and dispensing both dry and wet powders and granules. Its unique filtration concept with a flat membrane makes it the only vacuum dense-phase system available on the market today.